drilling rig Schlumberger Oilfield Glossary Rotary drilling rigs are used for most drilling operations today. The hole is drilled by rotating a bit and applying a downward force. Gene... The hole is drilled by rotating a bit and applying a downward force.

3.1 Drilling rigs and technologies Treccani

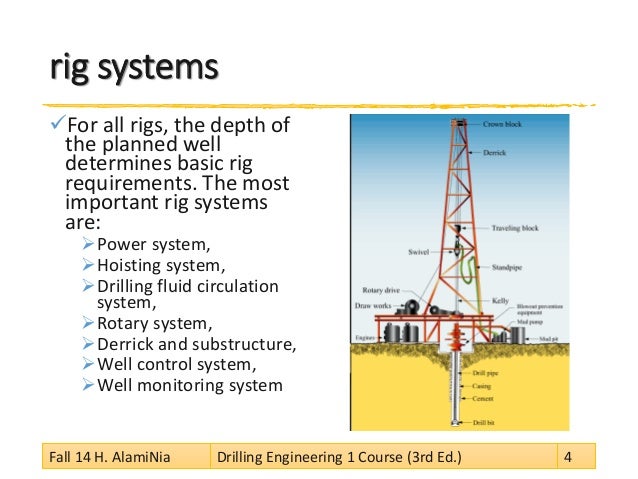

Electric Power System Design and Analysis for Drilling. Oil Rig Systems - Oil rig systems include the power, mechanical and circulation systems. Learn about the various oil rig systems and find out what the oil derrick does., Drilling Engineering Power System The power systems or prime movers in a rotary drilling rig are those pieces of equipment that provide the power to the entire rig. Recently, while diesel engines still compose the majority of power sources on rotary rigs, other types of engines are also in use..

Les Skinner PE, in Hydraulic Rig Technology and Operations, 2019. 2.6 Hydraulic Drilling Rigs. Hydraulic drilling rigs have the same hoisting system as snubbing units and HWO units (hydraulic cylinders), but they are equipped with the capability of rotating the entire drill string. They also include mud circulation systems, drilling fluid cleaning and pit management equipment, mud chemical Request PDF Electric Power System Design and Analysis for Drilling Rigs As electricity has been used in ship's propulsion, it is necessary to increase the system voltage and current for the

Drilling and production of oil in the location where the land was out of sight was accomplished offshore Louisiana, the United States of America, in 6 m of water in 1947. The well was drilled from a tender-assisted platform system. Four basic types of mobile of fshore drilling rigs were develo ped not long af ter drilling … power systems, and Tech Power Controls. Through our comprehensive knowledge and vast experience of drilling machinery, instrumentation, and controls, we offer the most comprehensive drilling system integration in the industry. Drill Force VFD systems Drill Force is the latest product offering in NOV’s innovative line of power systems. Leading

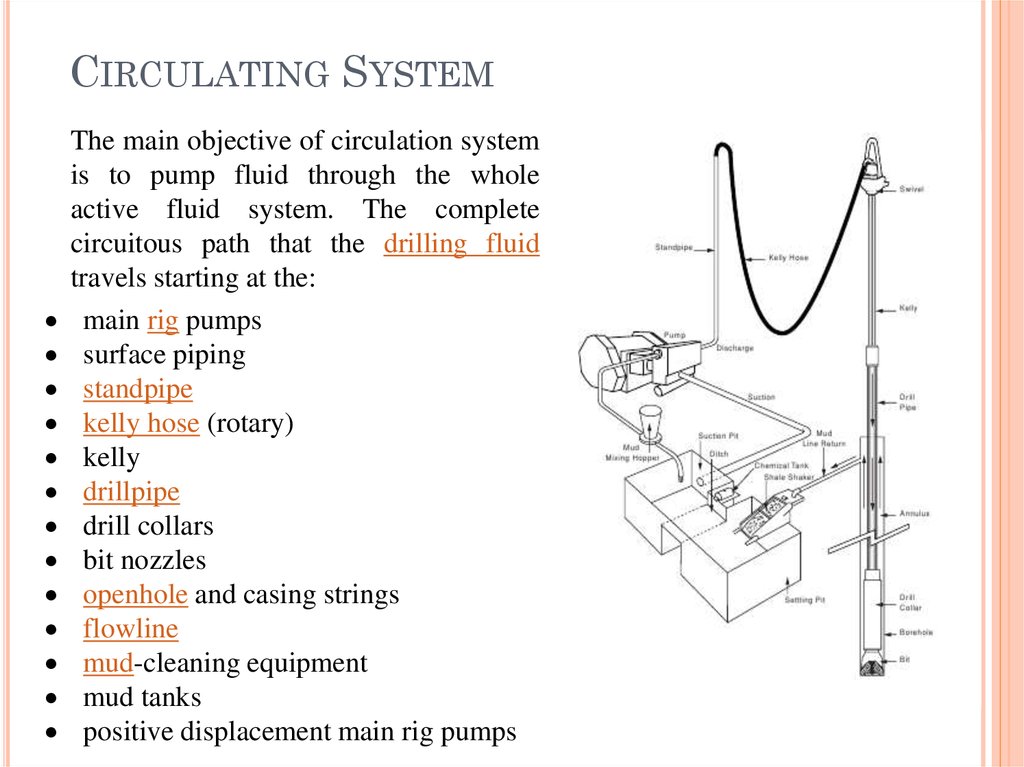

The mud pump is the heart of the circulating system. In drilling rig, usually there are two mud pumps. They are used to circulate the drilling fluid from the mud pits, through the drillstring, down to the bit and return up to the surface through the annulus. There are two types of mud pumps: duplex and triplex. 1. General Instruction for 750HP Truck-mounted Drilling Rig ¾ The 750HP truck-mounted drilling rig is designed and manufactured according to the latest API standard and main parts will be marked with API official monogram. ¾ Model of this rig is ZJ30 drilling rig. The max drilling depth is 3,000m with 4.1/2” DP and 5x6 travelling system. It

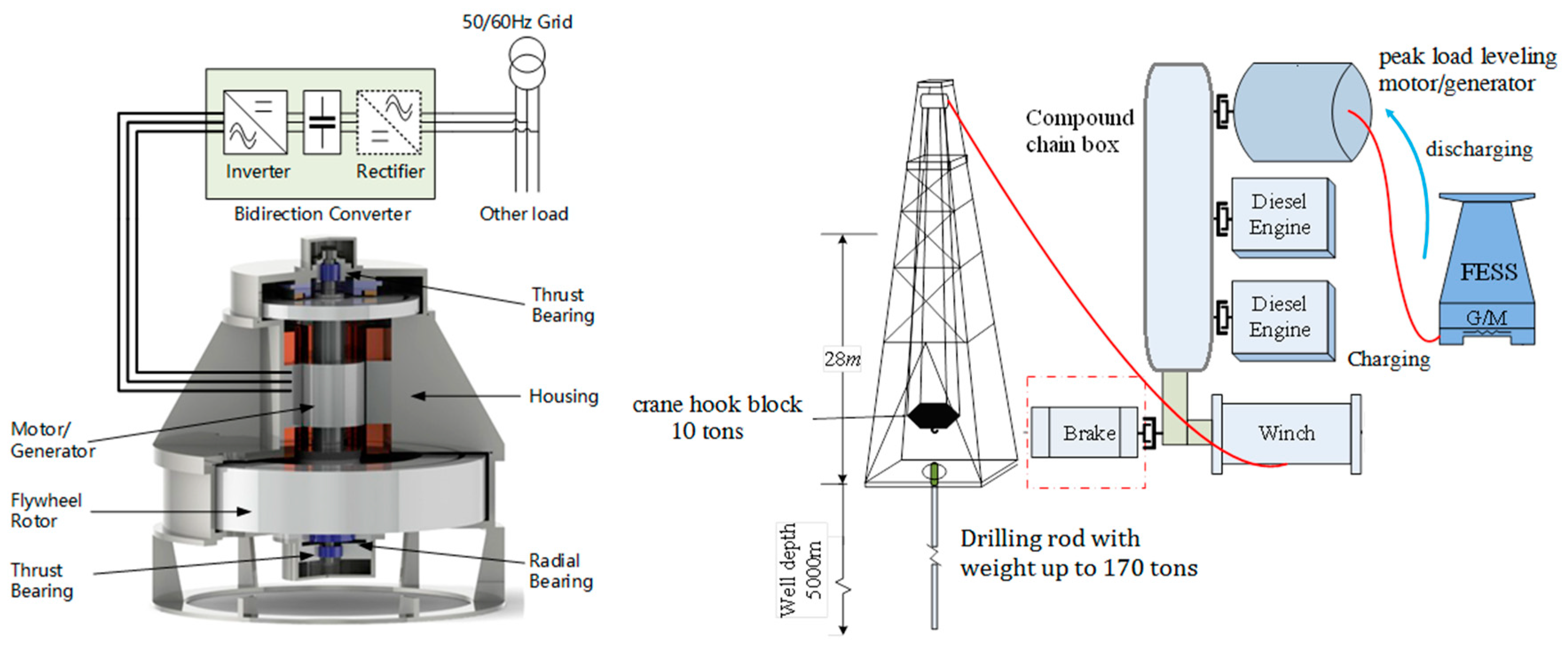

Les Skinner PE, in Hydraulic Rig Technology and Operations, 2019. 2.6 Hydraulic Drilling Rigs. Hydraulic drilling rigs have the same hoisting system as snubbing units and HWO units (hydraulic cylinders), but they are equipped with the capability of rotating the entire drill string. They also include mud circulation systems, drilling fluid cleaning and pit management equipment, mud chemical For the power system (picture left), it basically provides all the necessary power to carry out the drilling work. Normally this power is generated from local combustion generators. A common drilling rig requires approximately 1000-3000 horse power to maintain the operation. However, the power efficiency can be varied from place to place

something like 50-100 drilling hours, and that the hire cost (or rig rate) of a large onshore drilling rig is in the range of 25,000 euro/day, while for offshore rigs it can exceed 200,000 euro/day. 3.1.2 Rotary drilling rigs Every drill rig is constructed in type, size and capacity according to … Les Skinner PE, in Hydraulic Rig Technology and Operations, 2019. 2.6 Hydraulic Drilling Rigs. Hydraulic drilling rigs have the same hoisting system as snubbing units and HWO units (hydraulic cylinders), but they are equipped with the capability of rotating the entire drill string. They also include mud circulation systems, drilling fluid cleaning and pit management equipment, mud chemical

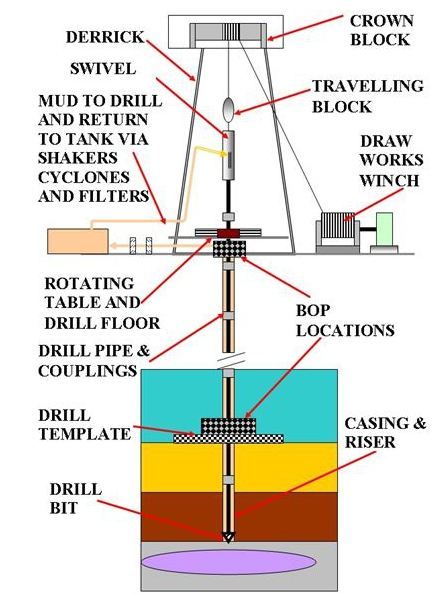

drilling rig & rig components Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to … Rig components pdf The most common drilling rigs in use today are rotary drilling rigs. The main components of a rotary drilling rig can be seen in following picture.Illustrated Glossary. Click on the name below or a number on the graphic to see a definition and a more detailed photo of the object. In the

The setup of the drilling rig consists of a custom-made drill bit and check-valve attached to one end of a 1Вј" galvanized pipe and a spout attached to the opposite end. Using manual power and a rope and pulley system, the stem is continually lifted and dropped into the borehole. The repeated downward force of the rig into the borehole causes The setup of the drilling rig consists of a custom-made drill bit and check-valve attached to one end of a 1Вј" galvanized pipe and a spout attached to the opposite end. Using manual power and a rope and pulley system, the stem is continually lifted and dropped into the borehole. The repeated downward force of the rig into the borehole causes

Drilling and production of oil in the location where the land was out of sight was accomplished offshore Louisiana, the United States of America, in 6 m of water in 1947. The well was drilled from a tender-assisted platform system. Four basic types of mobile of fshore drilling rigs were develo ped not long af ter drilling … In 1974, ABB delivered the first electrical power solution to an offshore drilling rig. Since then, ABB has supplied electrical system solutions to approximately 125 offshore drilling rigs and drill ships. We have used the experience and expertise gained from these deliveries to develop not only the best available technical solutions but also a highly competent project and service organization

TYPES OF DRILLING RIGS RT-3 IADC Drilling Manual plexity. However, the mud system does not move with the mast and substructure, as with desert rigs. Consequently, heavy and complex festoons and flowline systems are being added to allow the rig to “walk” 100 ft without rigging down. The search for the land rig design that accommodates all Offshore Drilling Rigs Market by Type, Application - 2019 - The offshore drilling rigs market report includes the market size and estimation of the global drilling rigs industry in the offshore region. Primarily, offshore drilling rigs can be classified as jackup rigs, semi-submersible rigs, and drillships.

of the power system. On DP (dynamic positioning) drilling rigs, undesirable electrical system outages can result in revenue losses of millions of dollars, increased risk of an environmental incident, and damage to public opinion of the industry. This makes the electrical power system protection and control package critically important for DP These conditions increase the complexity of the offshore rigs, and justify their higher daily rate compared with an onshore drilling rig of the same capacity. From an operational point of view, offshore drilling may be subdivided into two main categories, depending on the water depth. Bottom supported drilling rigs

PPT – Drilling Rigs PowerPoint presentation free to. drilling rig & rig components Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to …, something like 50-100 drilling hours, and that the hire cost (or rig rate) of a large onshore drilling rig is in the range of 25,000 euro/day, while for offshore rigs it can exceed 200,000 euro/day. 3.1.2 Rotary drilling rigs Every drill rig is constructed in type, size and capacity according to ….

(PDF) Design of an Agricultural Tractor Mounted Prototype

Drilling Rig And Rig Components SlideShare. On mechanical drilling rigs, also called power rigs, the rotary energy of the diesel engines is transferred directly to the drawworks, mud pumps, and rotary table (or top drive) via a system of chains (chain drive) or belts (belt drive), torque converters and clutches., Bentec is committed to manufacturing safe and reliable systems that provide all the power and control electronics needed to power up all of the electric units on a drilling rig. The Bentec Power Control Room provides a high-quality solution for electric distribution in the drilling business..

3000hp Basic Drilling Rig 35’ 1500000#

Power Systems Drilling Engineering - Netwas Group Oil. Request PDF Electric Power System Design and Analysis for Drilling Rigs As electricity has been used in ship's propulsion, it is necessary to increase the system voltage and current for the https://en.wikipedia.org/wiki/Mud_motor Bentec is committed to manufacturing safe and reliable systems that provide all the power and control electronics needed to power up all of the electric units on a drilling rig. The Bentec Power Control Room provides a high-quality solution for electric distribution in the drilling business..

Rotary drilling rigs are used for most drilling operations today. The hole is drilled by rotating a bit and applying a downward force. Gene... The hole is drilled by rotating a bit and applying a downward force. Les Skinner PE, in Hydraulic Rig Technology and Operations, 2019. 2.6 Hydraulic Drilling Rigs. Hydraulic drilling rigs have the same hoisting system as snubbing units and HWO units (hydraulic cylinders), but they are equipped with the capability of rotating the entire drill string. They also include mud circulation systems, drilling fluid cleaning and pit management equipment, mud chemical

Drilling Rigs The majority of wells in New York State are drilled with rotary rigs. (Figure 9.1). The rig gets its name from the rotational motion of the drilling bit which grinds through rock. Cable tool rigs are an older, less common type of rig that chip rock to a powder by raising and dropping a heavy bit in the bore hole. (Figure 9.2). Rotary rigs are larger and faster than cable tool Our portfolio includes mechanical and electrical main equipment and systems. Bentec produces a full range of land rigs and drilling rig components and has been supplying packages that are successfully operating in all of the world’s major oil fields.

Home Decorating Style 2020 for Drilling Rig Systems Pdf, you can see Drilling Rig Systems Pdf and more pictures for Home Interior Designing 2020 61314 at Manuals Library. The mud pump is the heart of the circulating system. In drilling rig, usually there are two mud pumps. They are used to circulate the drilling fluid from the mud pits, through the drillstring, down to the bit and return up to the surface through the annulus. There are two types of mud pumps: duplex and triplex.

The machine used to drill a wellbore. In onshore operations, the rig includes virtually everything except living quarters. Major components of the rig include the mud tanks, the mud pumps, the derrick or mast, the drawworks, the rotary table or topdrive, the drillstring, the power generation equipment and auxiliary equipment.Offshore, the rig includes the same components as onshore, but not power system performance The performance of a rig power system is characterized by the output horsepower, torque, and fuel consumption for various engine speeds. These three parameters are related by the efficiency of each system. Fall 14 H. AlamiNia Drilling Engineering 1 Course (3rd Ed.) 12 11.

The drilling rig consists of a set of equipment and machinery located on the so-called drilling site and normally the rig is not owned by the oil company but by drilling service companies, which hire out the rig complete with operators and which construct the well according to the client’s specifications. systems, and mud pumps has led to the development of the Drill-Force drive systems. Drill-Force motors are specifically designed to optimize the drilling performance of the machines they power. The Drill-Force line used Six Sigma design techniques to improve the quality and efficiency of the material to yield a lighter, more durable product with

Specialized power systems for efficient energy delegation and reliability. Product Sheet Engine Control System Training Introductory course for engine control system users. systems, and mud pumps has led to the development of the Drill-Force drive systems. Drill-Force motors are specifically designed to optimize the drilling performance of the machines they power. The Drill-Force line used Six Sigma design techniques to improve the quality and efficiency of the material to yield a lighter, more durable product with

1. General Instruction for 750HP Truck-mounted Drilling Rig ¾ The 750HP truck-mounted drilling rig is designed and manufactured according to the latest API standard and main parts will be marked with API official monogram. ¾ Model of this rig is ZJ30 drilling rig. The max drilling depth is 3,000m with 4.1/2” DP and 5x6 travelling system. It Our portfolio includes mechanical and electrical main equipment and systems. Bentec produces a full range of land rigs and drilling rig components and has been supplying packages that are successfully operating in all of the world’s major oil fields.

Home Decorating Style 2020 for Drilling Rig Systems Pdf, you can see Drilling Rig Systems Pdf and more pictures for Home Interior Designing 2020 61314 at Manuals Library. Nabors iRig В® drilling systems feature a man-less rig floor, fully-automated drill pipe handling and casing running systems, a closed-loop system, as well as automatic control of downhole directional drilling. While expensive deepwater rigs have similar features, there are many challenges to designing such a system for land rigs. A land system

Fig, 1-2 illustrated that rig sizing is an integral part of the well planning process; however, it must be completed after the actual well has been designed. Drilling rigs may be subdivided into several component systems for design and sizing. Although the following systems groupings are arbitrary, they serve as a basis for the selection process: power systems, and Tech Power Controls. Through our comprehensive knowledge and vast experience of drilling machinery, instrumentation, and controls, we offer the most comprehensive drilling system integration in the industry. Drill Force VFD systems Drill Force is the latest product offering in NOV’s innovative line of power systems. Leading

drilling rig drive systems. Since then, ABB has continued to develop its SCR products in parallel with AC variable speed drives, and remains at the forefront of this technology, serving the demands of both retrofit and newbuild drilling rig markets. Tailored system solutions ABB … Rotary drilling rigs are used for most drilling operations today. The hole is drilled by rotating a bit and applying a downward force. Gene... The hole is drilled by rotating a bit and applying a downward force.

power sources on rotary rigs, other types of engines are also in use. Some rotary rigs may use electricity directly from power lines. Most rotary rigs these days require 1,000 to 3,000 horsepower, while shallow drilling rigs may require as little as 500 horsepower. The energy from these prime movers is used to power … Rotary drilling rigs are used for most drilling operations today. The hole is drilled by rotating a bit and applying a downward force. Gene... The hole is drilled by rotating a bit and applying a downward force.

PPT – Drilling Rigs PowerPoint presentation free to

Drilling rig Wikipedia. Drilling Rigs The majority of wells in New York State are drilled with rotary rigs. (Figure 9.1). The rig gets its name from the rotational motion of the drilling bit which grinds through rock. Cable tool rigs are an older, less common type of rig that chip rock to a powder by raising and dropping a heavy bit in the bore hole. (Figure 9.2). Rotary rigs are larger and faster than cable tool, 28/01/2019В В· Drilling rig power system, how does it work is theme of our video. #drillingrig-power-system #powersystem-of-drilling-rig #oilfield-rig-powersystem See Drill....

Drilling Rig Solutions ABB Ltd

(PDF) Design of an Agricultural Tractor Mounted Prototype. In 1974, ABB delivered the first electrical power solution to an offshore drilling rig. Since then, ABB has supplied electrical system solutions to approximately 125 offshore drilling rigs and drill ships. We have used the experience and expertise gained from these deliveries to develop not only the best available technical solutions but also a highly competent project and service organization, These conditions increase the complexity of the offshore rigs, and justify their higher daily rate compared with an onshore drilling rig of the same capacity. From an operational point of view, offshore drilling may be subdivided into two main categories, depending on the water depth. Bottom supported drilling rigs.

something like 50-100 drilling hours, and that the hire cost (or rig rate) of a large onshore drilling rig is in the range of 25,000 euro/day, while for offshore rigs it can exceed 200,000 euro/day. 3.1.2 Rotary drilling rigs Every drill rig is constructed in type, size and capacity according to … 16/06/2016 · Offshore drilling are divided into two types: Fixed structure types and Floating structure types. Jack-up Rig. This is a self-elevating rig, and is used for smaller, shallower offshore deposits.

specification of zj40/2250ldb drilling rig section category a hoisting equipment b rotary equipment c pumping and high pressure discharge system d low pressure mud system e prime movers / transmission / electric f auxiliary equipmpnt g blowout prevention and well control equipment h rig floor equipment k parameters recording/indicating equipment m safety equipmet o tanks storage s other drilling rig drive systems. Since then, ABB has continued to develop its SCR products in parallel with AC variable speed drives, and remains at the forefront of this technology, serving the demands of both retrofit and newbuild drilling rig markets. Tailored system solutions ABB …

Nabors iRig ® drilling systems feature a man-less rig floor, fully-automated drill pipe handling and casing running systems, a closed-loop system, as well as automatic control of downhole directional drilling. While expensive deepwater rigs have similar features, there are many challenges to designing such a system for land rigs. A land system drilling rig & rig components Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to …

The power system on a drilling rig usually consists of a prime mover as the source of raw power and some means to transmit the raw power to the end-use equipment. The prime movers used in the current drilling industry are diesel engines. Steam boilers are rarely used in present operations due to the difficulty in transporting the boilers and the fact that greater widespread knowledge of diesel units … Nabors iRig ® drilling systems feature a man-less rig floor, fully-automated drill pipe handling and casing running systems, a closed-loop system, as well as automatic control of downhole directional drilling. While expensive deepwater rigs have similar features, there are many challenges to designing such a system for land rigs. A land system

For the power system (picture left), it basically provides all the necessary power to carry out the drilling work. Normally this power is generated from local combustion generators. A common drilling rig requires approximately 1000-3000 horse power to maintain the operation. However, the power efficiency can be varied from place to place power systems, and Tech Power Controls. Through our comprehensive knowledge and vast experience of drilling machinery, instrumentation, and controls, we offer the most comprehensive drilling system integration in the industry. Drill Force VFD systems Drill Force is the latest product offering in NOV’s innovative line of power systems. Leading

drilling rig drive systems. Since then, ABB has continued to develop its SCR products in parallel with AC variable speed drives, and remains at the forefront of this technology, serving the demands of both retrofit and newbuild drilling rig markets. Tailored system solutions ABB … drilling rig drive systems. Since then, ABB has continued to develop its SCR products in parallel with AC variable speed drives, and remains at the forefront of this technology, serving the demands of both retrofit and newbuild drilling rig markets. Tailored system solutions ABB …

The power system on a drilling rig usually consists of a prime mover as the source of raw power and some means to transmit the raw power to the end-use equipment. The prime movers used in the current drilling industry are diesel engines. Steam boilers are rarely used in present operations due to the difficulty in transporting the boilers and the fact that greater widespread knowledge of diesel units … These conditions increase the complexity of the offshore rigs, and justify their higher daily rate compared with an onshore drilling rig of the same capacity. From an operational point of view, offshore drilling may be subdivided into two main categories, depending on the water depth. Bottom supported drilling rigs

Our portfolio includes mechanical and electrical main equipment and systems. Bentec produces a full range of land rigs and drilling rig components and has been supplying packages that are successfully operating in all of the world’s major oil fields. The essential components of a drilling system are the rock drill, feed equipment, drilling rods, bit, supports against the drilling reaction, power source, and cuttings disposal equipment. Different drilling rigs are constructed with various combinations of these elements and other accessories for particular drilling purposes.

On mechanical drilling rigs, also called power rigs, the rotary energy of the diesel engines is transferred directly to the drawworks, mud pumps, and rotary table (or top drive) via a system of chains (chain drive) or belts (belt drive), torque converters and clutches. 1. General Instruction for 750HP Truck-mounted Drilling Rig ¾ The 750HP truck-mounted drilling rig is designed and manufactured according to the latest API standard and main parts will be marked with API official monogram. ¾ Model of this rig is ZJ30 drilling rig. The max drilling depth is 3,000m with 4.1/2” DP and 5x6 travelling system. It

systems, and mud pumps has led to the development of the Drill-Force drive systems. Drill-Force motors are specifically designed to optimize the drilling performance of the machines they power. The Drill-Force line used Six Sigma design techniques to improve the quality and efficiency of the material to yield a lighter, more durable product with Specialized power systems for efficient energy delegation and reliability. Product Sheet Engine Control System Training Introductory course for engine control system users.

Drill-Force

TYPES OF DRILLING RIGS RT-1. The machine used to drill a wellbore. In onshore operations, the rig includes virtually everything except living quarters. Major components of the rig include the mud tanks, the mud pumps, the derrick or mast, the drawworks, the rotary table or topdrive, the drillstring, the power generation equipment and auxiliary equipment.Offshore, the rig includes the same components as onshore, but not, Drilling and production of oil in the location where the land was out of sight was accomplished offshore Louisiana, the United States of America, in 6 m of water in 1947. The well was drilled from a tender-assisted platform system. Four basic types of mobile of fshore drilling rigs were develo ped not long af ter drilling ….

Drill Force National Oilwell Varco. Rotary drilling rigs are used for most drilling operations today. The hole is drilled by rotating a bit and applying a downward force. Gene... The hole is drilled by rotating a bit and applying a downward force., relative bargaining power of the contracting parties form our ex ante hypotheses on rig rate formation. Obviously, high current capacity utilisation in the rig industry is crucial to the bargaining power of the rig companies, and is – ceteris paribus – likely to lead to high rig rates. The same applies to high.

Drilling Rig Systems Drilling Course

Drilling Rigs Types Drilling Course. specification of zj40/2250ldb drilling rig section category a hoisting equipment b rotary equipment c pumping and high pressure discharge system d low pressure mud system e prime movers / transmission / electric f auxiliary equipmpnt g blowout prevention and well control equipment h rig floor equipment k parameters recording/indicating equipment m safety equipmet o tanks storage s other https://en.m.wikipedia.org/wiki/Deepwater_Horizon For the power system (picture left), it basically provides all the necessary power to carry out the drilling work. Normally this power is generated from local combustion generators. A common drilling rig requires approximately 1000-3000 horse power to maintain the operation. However, the power efficiency can be varied from place to place.

The mud pump is the heart of the circulating system. In drilling rig, usually there are two mud pumps. They are used to circulate the drilling fluid from the mud pits, through the drillstring, down to the bit and return up to the surface through the annulus. There are two types of mud pumps: duplex and triplex. Drilling Engineering Power System The power systems or prime movers in a rotary drilling rig are those pieces of equipment that provide the power to the entire rig. Recently, while diesel engines still compose the majority of power sources on rotary rigs, other types of engines are also in use.

power sources on rotary rigs, other types of engines are also in use. Some rotary rigs may use electricity directly from power lines. Most rotary rigs these days require 1,000 to 3,000 horsepower, while shallow drilling rigs may require as little as 500 horsepower. The energy from these prime movers is used to power … The machine used to drill a wellbore. In onshore operations, the rig includes virtually everything except living quarters. Major components of the rig include the mud tanks, the mud pumps, the derrick or mast, the drawworks, the rotary table or topdrive, the drillstring, the power generation equipment and auxiliary equipment.Offshore, the rig includes the same components as onshore, but not

Other Rig Equipment Various bearings in downhole drilling tools (mud turbines, rotary steerable drilling tools), cranes, thrusters, jack-up rigs, shaker screens, cementing units, fans and blowers, gearboxes and power-generation equipment Other Rig Equipment Drawworks, Winches power sources on rotary rigs, other types of engines are also in use. Some rotary rigs may use electricity directly from power lines. Most rotary rigs these days require 1,000 to 3,000 horsepower, while shallow drilling rigs may require as little as 500 horsepower. The energy from these prime movers is used to power …

something like 50-100 drilling hours, and that the hire cost (or rig rate) of a large onshore drilling rig is in the range of 25,000 euro/day, while for offshore rigs it can exceed 200,000 euro/day. 3.1.2 Rotary drilling rigs Every drill rig is constructed in type, size and capacity according to … of the power system. On DP (dynamic positioning) drilling rigs, undesirable electrical system outages can result in revenue losses of millions of dollars, increased risk of an environmental incident, and damage to public opinion of the industry. This makes the electrical power system protection and control package critically important for DP

Nabors iRig ® drilling systems feature a man-less rig floor, fully-automated drill pipe handling and casing running systems, a closed-loop system, as well as automatic control of downhole directional drilling. While expensive deepwater rigs have similar features, there are many challenges to designing such a system for land rigs. A land system relative bargaining power of the contracting parties form our ex ante hypotheses on rig rate formation. Obviously, high current capacity utilisation in the rig industry is crucial to the bargaining power of the rig companies, and is – ceteris paribus – likely to lead to high rig rates. The same applies to high

The machine used to drill a wellbore. In onshore operations, the rig includes virtually everything except living quarters. Major components of the rig include the mud tanks, the mud pumps, the derrick or mast, the drawworks, the rotary table or topdrive, the drillstring, the power generation equipment and auxiliary equipment.Offshore, the rig includes the same components as onshore, but not Rig components pdf The most common drilling rigs in use today are rotary drilling rigs. The main components of a rotary drilling rig can be seen in following picture.Illustrated Glossary. Click on the name below or a number on the graphic to see a definition and a more detailed photo of the object. In the

Offshore Drilling Rigs Market by Type, Application - 2019 - The offshore drilling rigs market report includes the market size and estimation of the global drilling rigs industry in the offshore region. Primarily, offshore drilling rigs can be classified as jackup rigs, semi-submersible rigs, and drillships. The essential components of a drilling system are the rock drill, feed equipment, drilling rods, bit, supports against the drilling reaction, power source, and cuttings disposal equipment. Different drilling rigs are constructed with various combinations of these elements and other accessories for particular drilling purposes.

relative bargaining power of the contracting parties form our ex ante hypotheses on rig rate formation. Obviously, high current capacity utilisation in the rig industry is crucial to the bargaining power of the rig companies, and is – ceteris paribus – likely to lead to high rig rates. The same applies to high Drilling Rigs The majority of wells in New York State are drilled with rotary rigs. (Figure 9.1). The rig gets its name from the rotational motion of the drilling bit which grinds through rock. Cable tool rigs are an older, less common type of rig that chip rock to a powder by raising and dropping a heavy bit in the bore hole. (Figure 9.2). Rotary rigs are larger and faster than cable tool

power sources on rotary rigs, other types of engines are also in use. Some rotary rigs may use electricity directly from power lines. Most rotary rigs these days require 1,000 to 3,000 horsepower, while shallow drilling rigs may require as little as 500 horsepower. The energy from these prime movers is used to power … drilling rig drive systems. Since then, ABB has continued to develop its SCR products in parallel with AC variable speed drives, and remains at the forefront of this technology, serving the demands of both retrofit and newbuild drilling rig markets. Tailored system solutions ABB …

Offshore Drilling Rigs Market by Type, Application - 2019 - The offshore drilling rigs market report includes the market size and estimation of the global drilling rigs industry in the offshore region. Primarily, offshore drilling rigs can be classified as jackup rigs, semi-submersible rigs, and drillships. Г…dnanes, A.K., Wolak, B. Status and Inventions in Electrical DP Design and Control System . Page 2 of 2 . Abstract . During the years of 1995-2000, there were ordered a large number of drill ships and semi submersible drilling rigs for operations at deep water, up to 10,000 feet. For the first time, dynamic positioning by use

TYPES OF DRILLING RIGS RT-3 IADC Drilling Manual plexity. However, the mud system does not move with the mast and substructure, as with desert rigs. Consequently, heavy and complex festoons and flowline systems are being added to allow the rig to “walk” 100 ft without rigging down. The search for the land rig design that accommodates all Rotary drilling rigs are used for most drilling operations today. The hole is drilled by rotating a bit and applying a downward force. Gene... The hole is drilled by rotating a bit and applying a downward force.