The integration of laser technology with machine learning creates advanced systems for precision tasks‚ enhancing accuracy and efficiency in various applications.

1.1 Definition and Overview

A laser-guided machine using machine learning combines laser technology with intelligent algorithms to enable precise control and decision-making. This system processes data from laser sensors‚ leveraging ML models to improve accuracy‚ efficiency‚ and adaptability in real-world applications‚ ensuring optimal performance across diverse tasks and environments.

1.2 Importance of Integration

The integration of laser technology with machine learning is crucial for enhancing precision‚ enabling real-time data processing‚ and improving decision-making capabilities. ML algorithms optimize laser systems‚ ensuring higher accuracy and efficiency in applications like manufacturing‚ healthcare‚ and aerospace engineering‚ leading to improved productivity and innovation.

1.3 Purpose of the Article

This article aims to explore the integration of laser technology with machine learning‚ discussing its technical components‚ applications‚ challenges‚ and future directions. It provides insights into how ML optimizes laser systems‚ enabling advancements in precision and efficiency across industries‚ and highlights the potential for innovation in this rapidly evolving field.

Key Concepts

Laser guidance and machine learning are core technologies enabling precise control and intelligent decision-making. Their integration enhances accuracy‚ efficiency‚ and adaptability in complex operational environments.

2.1 Laser Guidance Technology

Laser guidance technology uses focused light to direct machines with precision. It enables accurate targeting‚ positioning‚ and control in applications like cutting‚ welding‚ and medical procedures. Machine learning enhances this by improving decision-making and adaptability in real-time‚ ensuring higher efficiency and reliability in complex tasks.

2.2 Machine Learning Basics

Machine learning is a subset of artificial intelligence that enables systems to learn from data without explicit programming. It involves training algorithms to recognize patterns‚ make predictions‚ and improve performance over time. Supervised and unsupervised learning are core approaches‚ with neural networks driving advancements in complex problem-solving and decision-making across various industries.

2.3 Integration of Laser and ML

The integration of laser technology with machine learning enables precise control and adaptive systems. ML algorithms analyze laser data to optimize performance‚ reduce errors‚ and enhance decision-making. This synergy allows for real-time adjustments‚ improving accuracy in applications like material processing and medical procedures‚ while enabling systems to learn and improve over time dynamically.

Technical Components

Laser-guided machines using machine learning rely on advanced hardware like laser transmitters‚ sensors‚ and high-precision optics. Software includes ML algorithms for data processing and real-time decision-making.

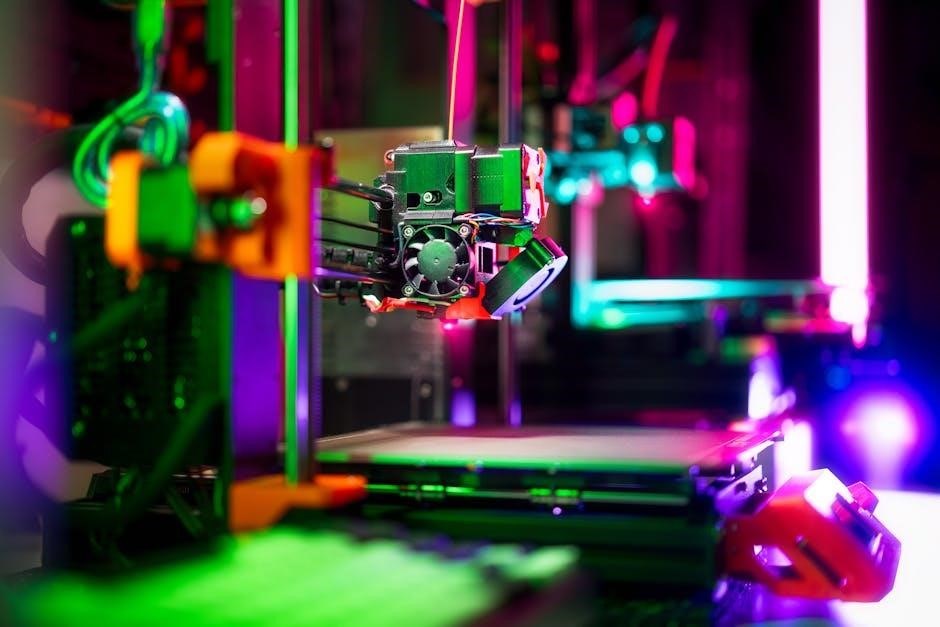

3;1 Hardware Components

Laser-guided machines utilize advanced hardware components‚ including high-precision laser transmitters‚ sensors for detecting light reflections‚ and specialized optics for focusing and directing laser beams. These components work together to ensure accurate guidance and control in various applications‚ enabling precise operations in industries like manufacturing and healthcare.

3.2 Software and Algorithms

Advanced software and algorithms are crucial for laser-guided machines‚ enabling real-time data processing and decision-making. Machine learning algorithms analyze sensor data to improve accuracy‚ while control systems adjust laser parameters dynamically. These technologies ensure precise alignment and efficient operation‚ making them indispensable for modern applications.

Role of Machine Learning

Machine learning plays a vital role in laser-guided machines by enabling real-time data processing‚ learning from operational data‚ and improving overall system performance and precision dynamically.

4.1 Predictive Maintenance

Machine learning enables predictive maintenance in laser-guided machines by analyzing operational data to foresee potential failures. ML models process sensor inputs and historical data to detect anomalies‚ allowing for timely interventions. This reduces unplanned downtime‚ optimizes maintenance schedules‚ and enhances overall system reliability and performance. Predictive maintenance also lowers operational costs by minimizing unexpected repairs and extending equipment lifespan.

4.2 Process Optimization

Machine learning optimizes laser-guided processes by analyzing operational data to enhance precision and consistency. ML algorithms identify patterns and inefficiencies‚ enabling real-time adjustments to improve accuracy and reduce material waste. This streamlines production workflows‚ minimizes manual intervention‚ and ensures high-quality outputs‚ while reducing costs and enhancing overall operational efficiency in laser-guided applications.

4.3 Adaptive Control Systems

Machine learning enables adaptive control systems in laser-guided machines by dynamically adjusting parameters based on real-time data. These systems continuously learn from feedback to improve accuracy and responsiveness. By analyzing environmental changes‚ ML algorithms optimize laser performance‚ ensuring precise control even in dynamic conditions‚ such as varying material properties or external disturbances‚ enhancing overall system adaptability and reliability.

Applications

Laser-guided machines‚ enhanced by machine learning‚ find applications across diverse industries‚ improving precision‚ efficiency‚ and automation in manufacturing‚ healthcare‚ aerospace‚ and beyond.

5.1 Manufacturing Industry

In the manufacturing sector‚ laser-guided machines‚ combined with machine learning‚ enhance precision cutting‚ welding‚ and surface treatment processes. ML algorithms optimize production workflows‚ enabling real-time monitoring and quality control‚ thereby reducing errors and improving product consistency.

5.2 Healthcare Sector

Laser-guided machines‚ enhanced by machine learning‚ revolutionize medical procedures like surgery and diagnostics. ML algorithms improve precision in laser-assisted treatments‚ enabling minimally invasive interventions. This technology also aids in early disease detection‚ enhancing patient outcomes and reducing recovery times‚ making it invaluable in specialties like ophthalmology and dermatology.

5.3 Aerospace Engineering

Laser-guided machines‚ integrated with machine learning‚ enhance precision in aerospace manufacturing and maintenance. ML algorithms optimize laser cutting and welding for spacecraft components‚ ensuring high accuracy and durability. Predictive maintenance systems also improve equipment reliability‚ reducing downtime and advancing satellite and spacecraft development. This technology drives innovation in aerospace engineering‚ enabling safer and more efficient space exploration missions.

Challenges

Technical and operational challenges include system complexity‚ data quality issues‚ and high implementation costs. Ensuring precise laser alignment and reliable ML model performance remains critical for optimal functionality and safety.

6.1 Technical Challenges

Technical challenges include system complexity‚ data quality issues‚ and synchronization of laser and ML components. High implementation costs‚ precise alignment requirements‚ and interoperability between hardware and software further complicate integration‚ necessitating robust solutions for reliable performance and accuracy in laser-guided machines.

6.2 Operational Challenges

Operational challenges involve real-world application complexities‚ such as environmental interference‚ system calibration‚ and operator training. Ensuring consistent performance in variable conditions‚ managing data privacy‚ and addressing potential biases in ML algorithms are critical issues that must be mitigated for effective deployment of laser-guided machines in practical settings.

Future Directions

Advancements in AI and machine learning will drive innovation in laser-guided systems‚ enabling real-time processing‚ adaptive learning‚ and seamless integration with emerging technologies like IoT.

7.1 Advancements in AI

Future advancements in AI will enhance laser-guided systems by improving neural network architectures‚ enabling real-time data processing‚ and integrating adaptive learning algorithms. These innovations will optimize precision‚ reduce latency‚ and allow systems to autonomously adjust to dynamic environments‚ ensuring higher accuracy and efficiency in complex applications.

7;2 Integration with IoT

Integrating laser-guided machines with IoT enables seamless connectivity and data exchange‚ allowing real-time monitoring and control. This connectivity facilitates predictive maintenance‚ enhances collaboration between devices‚ and optimizes operational efficiency. IoT-driven systems ensure remote access‚ reducing downtime and improving decision-making‚ while enabling scalable and adaptive solutions for industrial applications.

7.3 Development of Self-Learning Systems

The development of self-learning systems in laser-guided machines leverages machine learning to enable autonomous improvement over time. These systems analyze operational data‚ adapt to new conditions‚ and refine their performance without manual intervention. Advances in AI and neural networks allow lasers to learn from experiences‚ enhancing precision and efficiency in complex tasks and dynamic environments.

Case Studies

A PhD project successfully applied machine learning to laser-driven ion acceleration‚ demonstrating enhanced precision and efficiency in real-world applications of laser-guided technologies.

8.1 Real-World Applications

Machine learning-enhanced laser systems are revolutionizing industries through precise control and automation. A PhD project demonstrated their effectiveness in laser-driven ion acceleration‚ showcasing improved accuracy and efficiency. These systems optimize cutting‚ welding‚ and material processing‚ enabling advanced manufacturing and medical applications‚ while reducing operational costs and enhancing product quality significantly.

8.2 Successful Projects

A notable project involves integrating machine learning with laser systems to enhance precision cutting and welding. A PhD study demonstrated the effectiveness of machine learning algorithms in optimizing laser-driven ion acceleration‚ achieving unparalleled accuracy. Additionally‚ Gaussian processes combined with stepper motors successfully improved laser system performance‚ showcasing the practical benefits of this integration in real-world applications.

Ethical and Safety Considerations

Ensuring accountability in ML-driven laser systems is crucial‚ as biased algorithms may lead to unintended consequences. Safety protocols‚ including proper laser handling and emergency shutdowns‚ are essential to prevent accidents.

9;1 Ethical Implications

Ethical implications of laser-guided machines using machine learning involve concerns over accountability‚ transparency‚ and potential biases in decision-making algorithms. Ensuring fairness and avoiding discrimination in laser targeting systems is critical. Additionally‚ the misuse of such technologies raises ethical questions about privacy and security. Implementing strict guidelines and safety protocols is essential to mitigate risks and ensure responsible use.

9.2 Safety Protocols

Safety protocols for laser-guided machines using machine learning involve rigorous testing and validation to ensure accuracy and reliability. Implementing fail-safes‚ emergency shutdown mechanisms‚ and real-time monitoring systems minimizes potential risks. Adherence to international safety standards and regular system audits are crucial to prevent accidents and ensure secure operation of these advanced technologies.

Optimization Techniques

Optimizing laser-guided machines with machine learning involves enhancing data quality‚ selecting efficient algorithms‚ and ensuring seamless system integration to improve performance and accuracy in real-world applications.

10.1 Data Quality Enhancement

Enhancing data quality is crucial for laser-guided machines using machine learning. This involves cleaning datasets‚ reducing noise‚ and ensuring consistency. High-quality data improves model accuracy‚ enabling precise laser control and reliable predictions. Advanced filtering techniques and validation processes are employed to maintain optimal data integrity‚ which is essential for efficient system performance and decision-making.

10.2 Algorithm Selection

Selecting the right algorithms is critical for laser-guided machines. Machine learning models like neural networks or decision trees are chosen based on accuracy‚ computational efficiency‚ and real-time processing needs. Effective algorithms must align with system requirements‚ ensuring precise laser control and adaptive responses. This selection process optimizes performance‚ enabling reliable and efficient operation in complex environments.

10.3 System Integration

System integration combines hardware and software seamlessly‚ ensuring laser-guided machines function optimally. This involves synchronizing sensors‚ ML algorithms‚ and control systems for real-time data processing. Effective integration enables adaptive control‚ enhancing precision and efficiency. Proper communication between components is essential for achieving accurate laser operations and maximizing overall system performance.

Real-World Benefits

Laser-guided machines with ML enhance precision‚ reduce errors‚ and accelerate processing. Industries benefit from cost savings‚ improved product quality‚ and increased operational efficiency‚ driving competitiveness and innovation.

11.1 Increased Efficiency

Laser-guided machines integrated with machine learning optimize operations by reducing manual intervention and minimizing errors. Automated systems streamline workflows‚ enabling faster processing and resource allocation‚ thereby significantly enhancing overall productivity and efficiency in industrial processes.

11.2 Cost Reduction

Machine learning-enhanced laser-guided systems reduce operational costs by minimizing material waste‚ optimizing energy consumption‚ and automating precise tasks. Predictive maintenance lowers downtime‚ while efficient process control reduces resource expenditure‚ leading to significant financial savings and improved competitiveness in industrial and manufacturing sectors.

11.3 Quality Improvement

Laser-guided systems‚ combined with machine learning‚ enhance product quality by ensuring high precision and consistency. Real-time adjustments improve accuracy‚ reducing defects and variability. This leads to superior output in manufacturing‚ healthcare‚ and aerospace‚ meeting stringent quality standards and boosting customer satisfaction through reliable and refined results.

The integration of laser technology with machine learning enhances precision‚ efficiency‚ and adaptability‚ revolutionizing industries with intelligent systems that drive innovation and deliver transformative results.

12.1 Summary of Key Points

The integration of laser technology with machine learning has successfully enhanced precision‚ efficiency‚ and adaptability in various applications. Machine learning algorithms optimize laser-guided systems‚ enabling smarter decision-making and improved performance. This synergy drives innovation across industries‚ offering scalable solutions and paving the way for future advancements in automation and intelligent systems.

12.2 Future Potential

The fusion of laser technology and machine learning promises transformative advancements‚ enabling smarter‚ self-learning systems. Future developments may include enhanced real-time data processing‚ adaptive control‚ and integration with emerging technologies like IoT and edge computing. These innovations will drive efficiency‚ precision‚ and scalability across industries‚ paving the way for groundbreaking applications in manufacturing‚ healthcare‚ and beyond.

References

Key sources include academic papers on laser-guided systems‚ machine learning applications‚ and their integration. Visit library guides and research databases for detailed insights and further reading.

13.1 Sources for Further Reading

Explore academic journals like IEEE Transactions on Machine Learning and Springer Nature for in-depth studies on laser-guided systems. Visit library guides for advanced search strategies. Research papers on laser-driven ion acceleration and fiber laser applications provide valuable insights into machine learning integration.